Home ->

PLID Float Coat

S2S FLOAT COAT – LIQUID PREVENTATIVE MAINTENANCE

S2S Float Coat is a long lasting, cost effective solution for combating corrosion in tight & confined spaces

S2S Float Coat was specially designed to meet the following criteria

- It floats on top of water (forming a continuous layer on the surface), polar bonds to metal it comes into contact with and displaces water and oxygen.

- It surpassed the US Navy Mil Spec 16713 salt spray test requirements (323 hours) by lasting 500 hours in a salt spray chamber. This success can be attributed to S2S Float Coat’s ideal viscosity; it is thin enough to float in a continuous layer on the water yet thick enough to protect metal from rust for a lengthy period of time.

- Its water discharge meets the environmentally strict standards set by the state of California, which means that 90% of the discharge from an S2S float coat can be safely pumped into the ocean. The final 10% should be recovered and disposed of in accordance with local regulations.

FLOAT COAT - MARITIME SUBMARINES

The Canadian Navy used S2S Plid Float Coat on their submarine rudders.

PLID Float Coat Available Sizes

- 20 litre pail (5 gal)

- 205 litre drum (55 gal)

Float Coat Application Guide

Personal Protection Equipment

Organic vapour respirator cartridge, Tyvek suit,

non-slip oil resistant gloves, safety glasses or

protective eyewear, work boots.

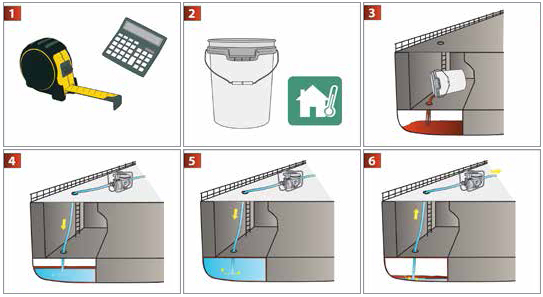

S2S PLID Float Coat Procedure

- S2S PLID Float Coat (PLID FC) procedure will yield 100% coverage of all contacted surfaces in one operation.

- The unit being coated can be damp on the inside before installation of PLID FC.

- PLID FC will attach to the surface at approximately 1 mil.

- Calculate the volume of material required for a 1 mil coat on all surfaces. Coverage per gal of PLID FC at 1 mil. = 280 square feet.

- To this volume, add additional 20% PLID FC so several inches remain on the surface of the water after it has been drained down.

- Gently add water (preventing excess turbulence) until the unit is completely filled so PLID FC contacts the top of the unit. Drain out the water, leaving the extra PLID FC in the unit.

Calculation for Amount of Float Coat required

S2S coverage for Float Coat is 4.8M2 per Litre and so a 20 Litre Pail will coat around 96M2 and a 205 Litre Drum 984M2 but add 20% volume to your calculation for the procedure to ensure sufficient is in the confined space being coated.

Procedure for units with heavy rust scale

- Proceed as above but allow more time and volume of PLID FC to soak into the rust scale. A second up & down cycle may be prudent.

- Note: Be aware, after a few months the

rust scale will delaminate and begin falling off,

which may cause clogging of pump screens

etc.

A second application may be required after a year or so as most rust scale will have fallen off, leaving unprotected metal. - Note: The PLID FC that is left sitting in the bottom of the unit will seep and cover bare spots that may be caused as minor rust scales detach and fall off. In this manner, self-healing will continuously occur.

- PLID FC may be used as a liquid descaler. Apply as above and check in a year’s time.

S2S Float Coat Alternative Method for Applying is as follows:

- Fill the area up almost to the top with water. Pour in the required amount of S2S and allow to settle then slowly pump in water from the bottom until the S2S reaches the top of the compartment or void space.

- With this method you do not have to wait for the S2S to all float back up to the top.

- Now slowly pump out the water from the bottom.

- The S2S will coat on the way down.

- When the S2S reaches the pump inlet shut down the pump unless you want to pump out remaining S2S.

Bolts, Flanges, Pipes and Pipe Lines

- S2S PLID INDUSTRIAL

- Flange painting spec. If the flanges are to be painted, a porous paint should be used so S2S can penetrate through to the surface of the metal.

- A cheap primer works well.

- The procedure below is the same for painted or unpainted flanges.

- Apply a heavy coat of S2S on the face of the flanges to be mated.

- Apply in the flange bolt holes and on the flange around the holes where the bolt head and washers will seat.

- Coat all bolts (under the heads as well) and washers (if any) and install through holes in flanges.

- Coat any washers, going under the nuts and install nuts.

- Once completed as above, it is good practice to coat the entire exterior of the flange assembly with S2S PLID Industrial.

- NOTE: Torque specifications will need to be adjusted for lubricated bolts.

- S2S works well as an assembly lube on O-rings and others requiring an assembly lube.

- NOTE: If the piping has a CP system installed, a check to be sure the current is passing through the joint is necessary; if it is not passing through, a jumper may need to be installed.

- If the entire pipeline is coated with S2S, there is no need for cathodic protection for the exterior of the piping.

Steel Cable

- To ensure long term protection and a thorough coating of the inner fibers, an initial application of S2S PLID Thin is recommended.

- S2S PLID Industrial can be used as a top coating for harsher environments.

- Can be treated by spraying during cable retraction.

- Can be dunked in a tank or drum of S2S.

- Some customers leave cable soaking in a tank when cable not in use, during off season.

- S2S will keep cable lubricated and fully flexible and does not need to be removed like traditional cable grease.

Anchor Chain

- S2S may be sprayed or brushed on chains.

- S2S will creep into the difficult to reach areas between links.

- One application method is to use a crane to hoist chain above a tank and slowly lower the chain as the links are coated.

- Another method is to lay chain out on a plastic sheet and apply on the ground with brush or sprayer, then flip the chain to coat opposite side.

- Do not over coat the chain or excess product will become airborne during deployment.

- S2S PLID Industrial may be applied over existing paint and rust.

Electrical & Electronics

- Apply S2S directly to circuit boards.

- Apply S2S to wires and breakers with power off.

- S2S should eliminate electrical and electric failure due to corrosion.

- If untreated electronics are accidently submerged in water, keep in water until able to treat with S2S PLID Thin film, then remove electronics from water and spray with S2S PLID Thin film until coated. This will displace moisture and salt, keeping the item rust free.

For further advice about the range of PLID Float Coat, PLID Heavy Duty Film, PLID Thin Film, Industrial Thick Film or PLID Wrap, give us a call on (03) 9587 6022 or drop us a line!

EMAIL US