SHIP 2 SHORE - RUST PREVENTION, ANTI-CORROSION - HOW DOES IT WORK?

S2S wet films are all from the same

PLID family & work the same way.

PLID is an acronym for…

Penetrant

Lubricant

Inhibit Rust

Dielectric

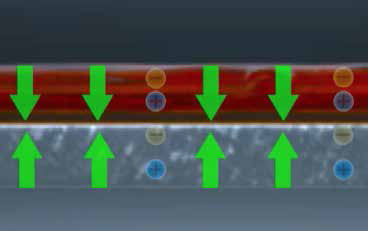

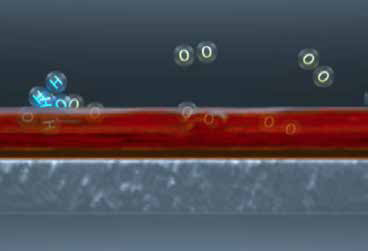

S2S Products Polar Bonding to Metal

Ship-2-Shore products work by polar bonding to the metal, displacing oxygen and water, forming an even, dripless dielectric barrier over the metal.

The products are all self-healing and will remain wet on the metal. You cannot paint over the products, however you can apply over paint.

The only way to remove the product, is to break the polar bond with a high PH soap.

Applying our products is simple. No surface preparation is required, also no training or certification is needed.

If the metal has a visible wet coating, the product is on and is working. It is either on and working or gone and no longer working.

S2S Products Better Deielectric and Penetration

The differences between the products is their thickness; the thicker the product, the longer it will last, the better lubricant it will be.

Thinner products have better dielectric and penetration capabilities.

Thicker versions also have less coverage and cost more for an initial application but are much more economical over the long term.

All products are non-toxic and non-hazardous. All products use kerosene as a solvent, which quickly flashes off after application. The warning symbols listed on the labels refer to the small percentage of kerosene contained in the products.

Gloves are recommended during application.

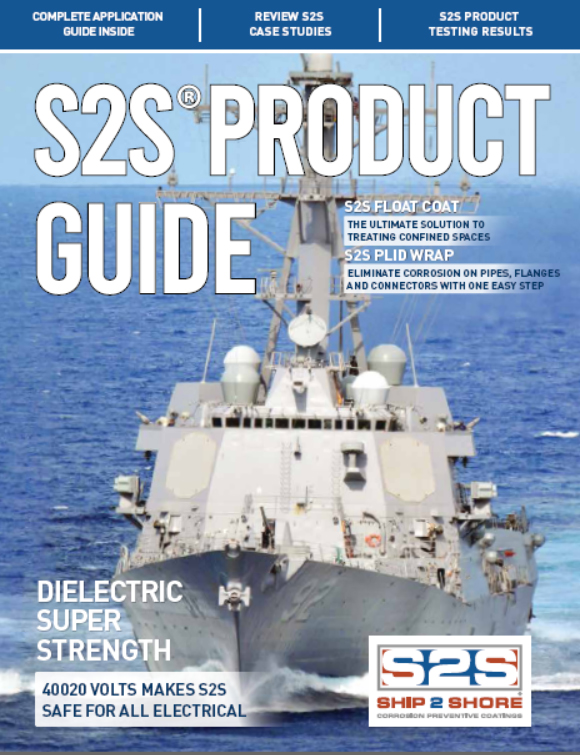

SHIP 2 SHORE PRODUCT GUIDE - S2S - Made for Industry

Download our product guide for more information on PLID Thin Film, PLID Industrial Thick Film, PLID Heavy Duty Film, PLID Float Coat and PLID Wrap - the ultimate products for prevention of rusting and anti-corrosion.

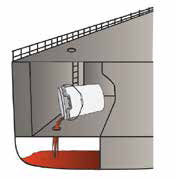

FLOAT COAT - HOW IT WORKS

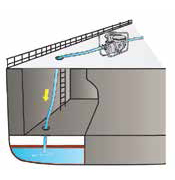

Measure & Pour S2S Float Coat

Calculate product

requirement: Each

gallon will coat 200

sq feet. Add 20% to

final calculation. A

pail coats 1000 sq

feet; a drum coats

10,000 sq feet.

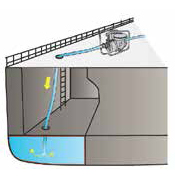

Gently & slowly pump in water

Place pump hose

at floor of tank and

slowly fill with water.

Note: S2S Float Coat

is lighter than water

and will float on top

and polar bond to the

metal as it rises

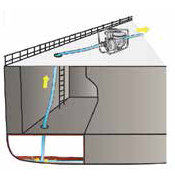

Fill void area to the top of space

When the water and

Float Coat reach

the top, turn off

the pump and let

the water settle for

24hours. This will

allow the Float Coat

to clearly separate

from the water.

Gently & slowly pump water out

Slowly pump the

water out from

the bottom. Use a

screen to filter out

rust flakes. The last

portion of the water

should be recaptured

so the product is not

pumped into ocean.

Guide for Estimating Required Amounts for S2S Products

Whilst there are a range of factors that will determine the amount of S2S product required for any given surface (the most significant being, if already corroded, coverage will be reduced) the following can be used as a guide to calculate the required volumes.

| PLID Thin Film | PLID Industrial | PLID HD | PLID Float Coat | |

| Coverage M2 per Litre | 6.5 | 3.5 | 2 | 4.6 |

| Thickness in Microns | 0.025 to 0.05 | 0.20 to 0.25 | 0.45 to 0.50 | 0.025 to 0.05 |

| Salt Spray Test Hours/Years lasting | 100/1 | 300/3 | 1000/10 | 500/5 |

N.B. To convert the coverage of Square Feet per US Gallon to Square Metres per Litre multiply by 0.024 e.g. 200 Square Feet per US Gallon (multiply 0.024) = 4.8 Square Metres per Litre

When deciding on product choice there are a range of factors that will need to be considered but when determining the real costs of protecting a given surface one has to consider the cost for a given period of time and so this requires both material costs and the application costs to be factored in as well as the frequency of repetition of applying the protection.

EMAIL US