RUST PREVENTION PUBLIC UTILITIES, PLANT & EQUIPMENT TESTIMONIALS

Ship-2-Shore Wet Films are made for a wide number of industries - utilities, plant and equipment. See the following testimonials proving high performance long lasting protection from moisture and corrosive contaminants and protection from rust.

Remote Steel I-Beam Highway Bridge Steep Creek British Columbia Sep 2014 to July 2014

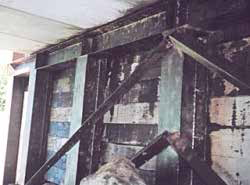

The I-beams on this remote bridge were so

badly rusted conventional preparation and

coatings were out of the question.

Ship-2-Shore was chosen as the only alternate

coating that could be used successfully in this

situation. Liquid Corrosion Control Systems

was contracted to do the work.

The I-beams on this remote bridge were so

badly rusted conventional preparation and

coatings were out of the question.

Ship-2-Shore was chosen as the only alternate

coating that could be used successfully in this

situation. Liquid Corrosion Control Systems

was contracted to do the work.

We first tried needle guns but most of the

scale was so tightly adhere needle guns were

ineffective. 10 pound smithy hammers banged

off some of the looser scale but a lot of tight

scale remaining. We applied Ship-2-Shore

"Industrial" to all the steel work right over the

tightly adhered rust scale we had been unable

to remove.

We first tried needle guns but most of the

scale was so tightly adhere needle guns were

ineffective. 10 pound smithy hammers banged

off some of the looser scale but a lot of tight

scale remaining. We applied Ship-2-Shore

"Industrial" to all the steel work right over the

tightly adhered rust scale we had been unable

to remove.

Six weeks later the Ministry of Transportation

and Highways bridge inspector reported back

and said "Ship-2-Shore application looks fine

but we will have to put more on." I asked if we

had missed some area, he said "No, the rust

scale is starting to fall off!"... of course this

takes the Ship-2-Shore off as well!

Six weeks later the Ministry of Transportation

and Highways bridge inspector reported back

and said "Ship-2-Shore application looks fine

but we will have to put more on." I asked if we

had missed some area, he said "No, the rust

scale is starting to fall off!"... of course this

takes the Ship-2-Shore off as well!

The bridge crew reapplied Ship-2-Shore as necessary. This is Liquid Descaling in Action! For more information contact us. Ten years later. All scale gone.

A couple of minor Ship-2-Shore touch-ups since 2004. Scale gone, Rusting STOPPED! 100% Simple, Easy, Effective Rust Control.

Rodger Smelcer VP, United Service Technologies, Anaheim, CA

"We use Ship-2-Shore PLID on food processing, preparation and cooking equipment in the meat department, deli and bakeries of our supermarket customers…we use it all kinds of places but especially on VFD's, circuit boards, connections and motors…they get wet and immediately start to corrode…it keeps them corrosion free…saves a ton of service calls and replacement parts…reduces equipment down time and saves our customer's a ton of money"

The Mushroom Composting Facility Jul 2002

Now in operation. Ship-2-Shore PLID is

working well to prevent corrosion on computer

boards in the loaders. In this high "ammonia"

environment, computer boards in the loaders

were lasting about 6 months before corroding

out at a cost of $3,000 each. This was getting

expensive.

Since they started spraying the boards with

PLID before putting them in service the

problem has been virtually eliminated.

One dollar invested returns $3,000 on saved

computer boards.

Grade Public Walkway West Bay Victoria BC Aug 2005

Steel walkway around marine harbour waterfront in Victoria BC.

We filled this moat with Ship-2-Shore "PLID"

which will migrate down the steel below grade.

We also put some higher up the post where

we will be using it as a primer before we paint

over it. (PLID is a highly effective penetrating,

moisture displacing rust inhibitor with a strong

attraction to metal).

Steel walkway around marine harbour waterfront in Victoria BC.

We filled this moat with Ship-2-Shore "PLID"

which will migrate down the steel below grade.

We also put some higher up the post where

we will be using it as a primer before we paint

over it. (PLID is a highly effective penetrating,

moisture displacing rust inhibitor with a strong

attraction to metal).

We topped up this moat with PLID as necessary every week or so, until an estimated cup or so had penetrated below grade. We waited until the moat was again empty then filled it with Ship-2-Shore Industrial (a thick long lasting water resistant rust inhibitor).

We covered the

moat with a thin

fiberglass sheet

cut to fit around the

base of the posts

secured with clear

silicone, not to seal

the join but to secure

the sheet in place.

It is not required to

be water tight. This

covering provides a

mechanical barrier

to prevent water

wash-out due to

heavy rains and

provides

UV protection.

When painting we allowed the paint to flow over

the Industrial below. I have since been back to

check things over and observed that the paint

has formed a tough hard coat over the

Ship-2-Shore Industrial.

This economical procedure works well for any

size steel structure, parkade or problem with

rebar rusting.

When painting we allowed the paint to flow over

the Industrial below. I have since been back to

check things over and observed that the paint

has formed a tough hard coat over the

Ship-2-Shore Industrial.

This economical procedure works well for any

size steel structure, parkade or problem with

rebar rusting.

Ken Wardstrom Wardstrom Industrial Gas Ltd. Jul 2004

“The anti-corrosion treatment you applied on our service trucks is proving very effective when compared to the trucks that were purposely not treated. The application of the ship to shore on the electrical terminal strip we were having problems with has solved the corrosion problem and the random shut downs have disappeared."

Al, Service Manager, Williams Machinery, Vancouver BC

"All our shop guys use it…no service vehicle leaves here without a least one can"

Lorne G., Canbuild Solutions, Nanaimo, B.C.

"We use PLID on all our tools and what-not. The guys like it because it lasts so long"

Robert Lodge, Mckay Lodge Conservation Laboratory, Oberlin, OH

"I recommend Ship-2-Shore PLID and Industrial to anyone for corrosion proofing…in my experience there is no better…it's worth it"

Lawrence Gilbert, Pluracom Atlantic Ltd., Distributor, Sydney Nova Scotia, Canada

"Attached is the photo of the test

sample. This sample has been out in the

weather for about 18 months.

The heavy rust area was bare steel, and you

can see the effects of corrosion. The darker

heavier product is the S2S industrial.

It is amazing to see where the S2S was

removed with the razor blade. The steel is in as

perfect condition as it was 18 months ago."

"Attached is the photo of the test

sample. This sample has been out in the

weather for about 18 months.

The heavy rust area was bare steel, and you

can see the effects of corrosion. The darker

heavier product is the S2S industrial.

It is amazing to see where the S2S was

removed with the razor blade. The steel is in as

perfect condition as it was 18 months ago."

"This sample has been out in the weather for about 18 months…the heavy rust area was bare steel…you can see the effects of corrosion…the darker heavier product is Ship-2-Shore Industrial…it is amazing to see where the Ship-2-Shore was removed…the steel is in perfect condition"

For further advice about the range of Thin Film, Industrial Thick Film, Thick Film, Float Coat or PLID Wrap, give us a call on (03) 9587 6022 or drop us a line!

EMAIL US