S2S PLID THIN FILM – TOTAL PREVENTATIVE MAINTENANCE

The Best Anti-Corrosion, Anti-Seize Lubricant & Penetrant

S2S PLID Thin Film Introduction

S2S PLID Thin Film seeps beneath the surface of metal providing superior corrosion protection. This product has the highest dielectric, to 40kV and so excellent for protecting electrical circuitry, electronics and stopping electrolysis.

Applications

S2S PLID Thin Film can be used on steel, steel alloy, stainless steel, galvanized, aluminum, tin, iron and copper. It has excellent adhesion to metal surfaces and resists splash, spray and complete submersion. PLID Thin Film shuts down corrosion and electrolysis and has a dielectric strength of 40,000 volts. It can be applied to materials from -35°C to 150°C.

S2S PLID Thin Film provides high performance protection from water and corrosive contaminants.

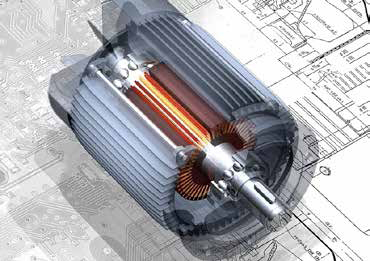

Advanced Thin Film Technology for Motors

- Penetrates existing rust and corrosion.

- Shuts down rust cells and halts electrolysis.

- Displaces moisture.

- Provides protection from water and corrosive contaminants.

- Works as a liquid descaler.

- Strong electromagnetic attraction to metals, like a magnet to steel, ensures adhesion long after other products disappear. Dielectric to 40,000 volts.

- Safe and effective for electronics, radios, circuit boards, electric motors, etc.

Protection for Circuit Boards

Use on integrated and printed circuit boards, conductors, connectors, contacts, electric connections, electric motors, wires, fasteners, screws, nuts and bolts, etc.

Protect valuable electronic equipment and electrical components with S2S Thin Film from corrosion.

Electronics - Avoid Replacement Parts & Service Costs

A significant cause of electric component failure is corrosion. Corrosion in electronic components is insidious and cannot be readily detected. When corrosion failure occurs, it is often dismissed as just a failure and the part or component is replaced. The most common reasons for corrosion related failure are atmospheric humidity and environmental contaminants.

PLID Thin Film Performance

| Physical State | Liquid |

| Colour | Dark Orange |

| Odour | Fresh Scent |

| Specific Gravity @15.6°C | 0.908 |

| Viscosity @40°C, cSt | 33 |

| Flash Point (COC), °C | 159 |

| Fire Point, °C | 171 |

| Pour Point, °C | -21 |

| Vapor Pressure | 8mm Hg at 25°C |

| Evaporation Rate | TBD |

| Water Solubility | TBD |

PLID Thin Film Available Sizes

- Aerosol 180g; box of 12

- 20 litre pail (5 gal)

- 205 litre drum (55 gal)

- 5 in 1 Wipes 10 Sachets 250mm x 300mm per carton

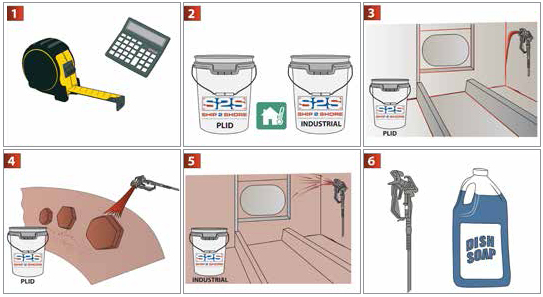

PLID Thin Film Application Guide

Personal Protection Equipment

Organic vapor respirator cartridge, Tyvek suit,

non-slip oil resistant gloves, safety glasses or

protective eyewear, work boots.

- Use a good quality foam roller.

- For best results, apply when temperatures are between 37° - 15°C (100° - 60°F).

- Can be used with 5-gallon pail.

- A simple, inexpensive application option but time consuming over large areas.

- Airless Sprayer must be able to flow at least 1 gallon per minute.

- Airless tips can range from a 315 – 521, based on temperature.

- For best results, apply when temperatures are between 37° - 15°C (100° - 60°F).

- When temperatures are below 15° - 4°C (60° - 40°F), a bigger pump will be needed. We recommend using a 30:1, with a hopper field, and a 3/8" hose no longer than 75m (225'), with a 1 m (3') whip line at 6 mm (1/4"). Tip size will need to be 317-521.

- In colder temperatures, band heaters must be used, with insulated lines.

- Pump pressure should never go over 60 or 3000 psi in the lines.

- Must have a working pressure of 20-40 psi.

- When temperatures are between 37° - 21°C (100° - 70°F), use 20 psi in up flow or bottom feed pot, with a 15 m (50') hose. Spray guns with D or E setups or 64 66 with air caps that match with same air atomizing air pressure will result in a uniform spray pattern.

- When temperatures are between 21° - 10°C (70° - 50°F), use 40 psi.

- When temperatures are below 10°C (50°F) bottom feed pot will need to be used. For best results, never use more than 60 psi or air bubbles will result.

- In temperatures below 5°C (42°F), heaters will need to be used in order to obtain adequate flow.

Preparation

- Before spraying, remove all debris, dirt, moisture, soap and degreaser.

Spraying

- In order to minimize overspray, always have the nozzle of the gun at a 90° angle.

- To reach desired thickness, make 2 – 3 passes.

- Ideal coat is 250 - 400 microns (10 – 16mm) thick.

Clean up

- Pour all remaining HD back into container and cover.

- Use warm water and soap to thoroughly clean spray equipment.

- If spray equipment will be used for another application of S2S products, a thorough cleaning of the lines is not necessary. However, if spray equipment will be going into storage, clean thoroughly and allow soapy water to remain in lines in order to avoid clogging.

Removal of S2S Wet Films

- Use high PH soap to break the polar bond.

- Pressure washer without use of High PH soap will not remove the products.

General Application Procedure

- Use PLID Thin film on all cracks, welds and bolts before general application, for deep penetration.

- Choose S2S PLID HD or S2S PLID Industrial for overall application, depending on the environment.

- If there is heavy scaling, apply S2S PLID Thin liberally over the scales and after 2 weeks they should fall off, then re-apply over the area with S2S PLID HD.

- Apply thicker coat over known problem areas and bottom quarter of interior hull walls.

- When coating extremely old, porous metal, double up on the coating thickness. S2S has a tendency to penetrate right into the pores of the metal leaving nothing on the surface.

Procedure for units with heavy rust scale

- Proceed as above but allow more time and volume of PLID FC to soak into the rust scale. A second up & down cycle may be prudent.

- Note: Be aware, after a few months the

rust scale will delaminate and begin falling off,

which may cause clogging of pump screens

etc.

A second application may be required after a year or so as most rust scale will have fallen off, leaving unprotected metal. - Note: The PLID FC that is left sitting in the bottom of the unit will seep and cover bare spots that may be caused as minor rust scales detach and fall off. In this manner, self-healing will continuously occur.

- PLID FC may be used as a liquid descaler. Apply as above and check in a year’s time.

Bolts, Flanges, Pipes and Pipe Lines

- S2S PLID INDUSTRIAL

- Flange painting spec. If the flanges are to be painted, a porous paint should be used so S2S can penetrate through to the surface of the metal.

- A cheap primer works well.

- The procedure below is the same for painted or unpainted flanges.

- Apply a heavy coat of S2S on the face of the flanges to be mated.

- Apply in the flange bolt holes and on the flange around the holes where the bolt head and washers will seat.

- Coat all bolts (under the heads as well) and washers (if any) and install through holes in flanges.

- Coat any washers, going under the nuts and install nuts.

- Once completed as above, it is good practice to coat the entire exterior of the flange assembly with S2S PLID Industrial.

- NOTE: Torque specifications will need to be adjusted for lubricated bolts.

- S2S works well as an assembly lube on O-rings and others requiring an assembly lube.

- NOTE: If the piping has a CP system installed, a check to be sure the current is passing through the joint is necessary; if it is not passing through, a jumper may need to be installed.

- If the entire pipeline is coated with S2S, there is no need for cathodic protection for the exterior of the piping.

Steel Cable

- To ensure long term protection and a thorough coating of the inner fibers, an initial application of S2S PLID Thin is recommended.

- S2S PLID Industrial can be used as a top coating for harsher environments.

- Can be treated by spraying during cable retraction.

- Can be dunked in a tank or drum of S2S.

- Some customers leave cable soaking in a tank when cable not in use, during off season.

- S2S will keep cable lubricated and fully flexible and does not need to be removed like traditional cable grease.

Anchor Chain

- S2S may be sprayed or brushed on chains.

- S2S will creep into the difficult to reach areas between links.

- One application method is to use a crane to hoist chain above a tank and slowly lower the chain as the links are coated.

- Another method is to lay chain out on a plastic sheet and apply on the ground with brush or sprayer, then flip the chain to coat opposite side.

- Do not over coat the chain or excess product will become airborne during deployment.

- S2S PLID Industrial may be applied over existing paint and rust.

Electrical & Electronics

- Apply S2S directly to circuit boards.

- Apply S2S to wires and breakers with power off.

- S2S should eliminate electrical and electric failure due to corrosion.

- If untreated electronics are accidently submerged in water, keep in water until able to treat with S2S PLID Thin film, then remove electronics from water and spray with S2S PLID Thin film until coated. This will displace moisture and salt, keeping the item rust free.

PLID Thin Film Standard Application Method

S2S Wet films are easy to apply, they can be brushed on, rolled on sprayed on with almost any type of spray applicator. No need to clean out your spray equipment after a spray session as the product remains wet and lubricates ready for the next application even if it months away. The product is easy to remove with a high PH soap, high pressure water alone will not remove the product until soap is added to break the polar bond to the metal.

PLID Thin Film Fill and Drain Method of Application

Any of the S2S wet films can be applied using this fill and drain method. This is perfect for rudders and voids. All recovered product can be used again and will not degrade. Several voids can be daisy chained from one space to the next, this is a simple effective way of treating a series of voids without complicated time consuming equipment.

PLID Thin Film - Deep Penetration

PLID Thin penetrates deep, watch it get to the core of this tightly bound steel cable protecting it from the middle out. For extra protection use the thicker films as a top layer, cable remains rust free and fully flexible!

PLID Thin Film - Great Penetrant and Lubricant

Watch the PLID Thin film creep up the metal, this is the self healing action caught on camera. This is why the Plid Thin film makes a great penetrant, creeping up rested bolts leaving them fully lubricated.

PLID Thin Film - Made for Industry

SHIP 2 SHORE PLID Thin Film is perfect in protecting from rust and corrosion in a wide range of industries including maritime, navy vessels, submarines, amphibious vehicles, ships, workboats, tugboats, barges, mining & resources military & security agricultural, farming equipment, food processing, public utilities, plant & equipment, transport recreational, sailing boats, motor vehicles. Also dielectric moisture prevention in electronics, circuit boards, switches, connectors, wiring and tools.

For further advice about the range of Thin Film, Industrial Thick Film, Thick Film, Float Coat or PLID Wrap, give us a call on (03) 9587 6022 or drop us a line!

EMAIL US